Presentations and posters are available for download:

Circular hydrometallurgy is the area of hydrometallurgy that focuses on the design of energy-efficient flowsheets or unit processes that consume a minimal amount of reagents and produce virtually no waste. It entails a different way of thinking about how hydrometallurgy is practiced, both for primary mining and recycling processes. Circularity refers to the regeneration and reuse of all the reagents in a process. This not only includes acids or bases used for leaching or pH control, but also any reducing agents, oxidising agents and other auxiliary reagents.

In addition to minimising the consumption of chemical reagents, the consumption of water and energy must be reduced to an absolute minimum. Deeply influenced by the concepts circular economy, eco-efficiency, green chemistry and green engineering, circular hydrometallurgy embraces the philosophy of “doing more with less”, providing a compass for future R&D in the field of hydrometallurgy.

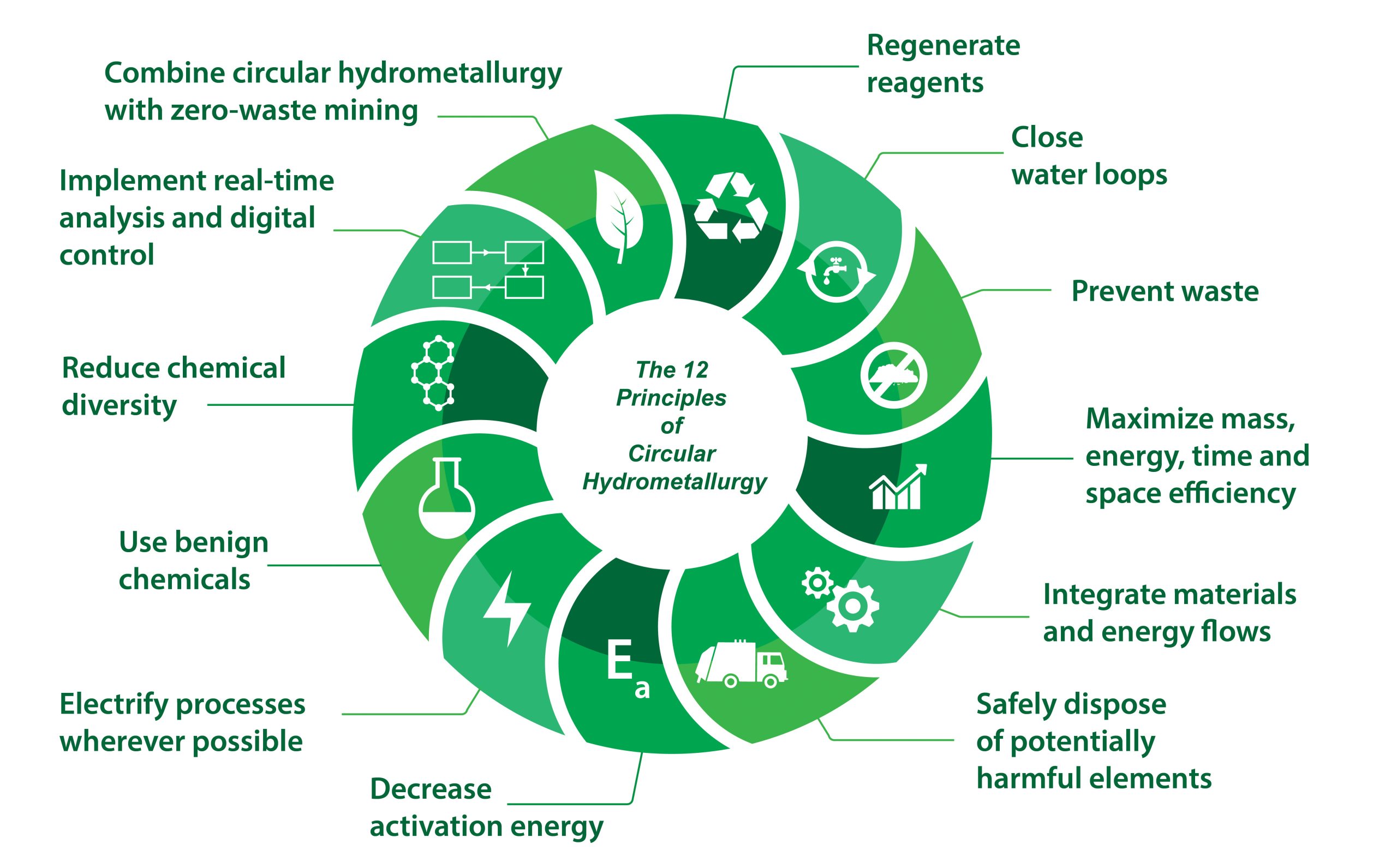

As a guiding framework of how circular hydrometallurgical flowsheets can be designed, a cohesive set of principles has been developed and published by SOLVOMET: i.e., the Twelve Principles of Circular Hydrometallurgy. These principles are design rules to help metallurgical engineers in achieving the goal of circularity in hydrometallurgy.

The 12 principles of circular hydrometallurgy are: (1) regenerate reagents; (2) close water loops, (3) prevent waste, (4) maximize mass, energy, space, and time efficiency, (5) integrate materials and energy flows, (6) safely dispose of potentially harmful elements, (7) decrease activation energy, (8) electrify processes wherever possible, (9) use benign chemicals, (10) reduce chemical diversity, (11) implement real-time analysis and digital process control, and (12) combine circular hydrometallurgy with zero-waste mining.

Koen Binnemans and Peter Tom Jones, The Twelve Principles of Circular Hydrometallurgy, Journal of Sustainable Metallurgy 9(1) (2023) 1-25.

Download from here (link: The Twelve Principles of Circular Hydrometallurgy | SpringerLink).

CALL FOR PAPERS: Circular Hydrometallurgy

A Special Issue for ‘Journal of Sustainable Metallurgy’ is dedicated to Circular Hydrometallurgy, an area of hydrometallurgy that focuses on the design of energy-efficient flowsheets or unit processes aimed at minimizing reagent consumption and producing virtually no waste.

Submission deadline: 1st February 2025

Prof. Koen Binnemans is an inorganic chemist and full professor at KU Leuven (Belgium). He is head of the Laboratory of Metallurgical Chemistry (SOLVOMET Group). His main research lines are: (1) critical metals, with a focus on energy-transition metals (rare earths, lithium, cobalt, nickel, manganese); (2) solvent extraction, (3) hydrometallurgy and (4) solvometallurgy. Koen Binnemans has created the concept of Circular Hydrometallurgy and its 12 Principles. Circular hydrometallurgy refers to the designing of energy-efficient and resource-efficient flowsheets or unit processes that consume the minimum quantities of reagents and result in minimum waste. The application of a circular approach involves new ways of thinking about how hydrometallurgy is applied for both primary and secondary resources.

Cost-effective processing and refining of lithium into lithium hydroxide from strategic European multi-mineral lithium hard-rock projects

Sustainable processing of Europe’s low grade sulphidic and lateritic Ni/Co ores and tailings into battery grade metals

MSA-based circular hydrometallurgy for sustainable, cost-effective production of NMC cathode materials

Cost-effective, sustainable and responsible extraction routes for recovering distinct critical metals and industrial minerals as by-products from key European hard-rock lithium projects

KU Leuven Institute for Sustainable Metals and Minerals one of the flagship Institutes endorsed by the KU Leuven Academic Council.

© 2025 All Rights Reserved SOLVOMET.